Flexographic printing

Foil lamination

Hot foilstamping

Personalization and numbering

Blind embossing

Protective varnish

Alternating labels

Free product-samples

Free form

Free delivery in the EU

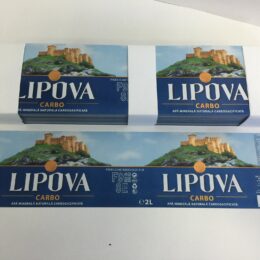

Beverage labels

We can produce a variety of beverage labels from dry paper labels on rolls to complex labels with embossing and die-cutting.

Options for making beverage labels:

- Dry label

- Labels on bottles and glass containers

- Transparent labels

- Counter-labels

- A label to be affixed near the neck of the bottle

The difference between standard labels and alcohol labels is that in the manufacture of self-adhesive labels a thin adhesive layer is applied. And then there is no need to apply glue to the bottle of alcohol. Bottle adhesive ensures strong adhesion of the label to the glass bottle.

Alcohol labels have their own specifics, for example beverages such as beer and vodka, requires cooling, resulting in condensation on the walls of the bottle and label. To protect the label, we resort to varnishing (varnish coating) or lamination, it gives it moisture resistance and a long service life. Technical specifications of self-adhesive labels, labels to be affixed near the neck of the bottle and counter labels for the bottle of alcohol managers europelabels.com approve with the customer.

The sticking of roll labels on a bottle of alcohol can be divided into 3 types:

1) manual

1) semi-automatic with label applicator

3) automatic with the help of a labeling machine printer-applicator, which prints the necessary information on the ready-made label and then sticks it on the package of products.

In the printing and production technological process, self-adhesive labels are wound into rolls. Depending on the type of applicator printer, label rolls are divided into winding types:

- out – standard (sealed side out);

- in – optional (sealed side inward).

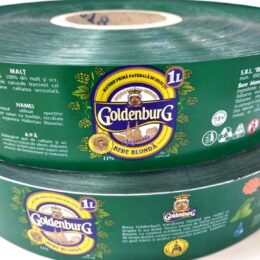

The roll printing from europelabels.com of self-adhesive bottle labels (water, lemonade, gin, vodka, wine, cognac) is possible on different substrates: paper, various films, metallized paper, synthetic. We use different types after the printing treatment of labels for alcoholic products: die-cutting of shaped labels, lamination, lacquering, foil stamping and embossing, application of holographic effects and holograms.

Post-treatment processes laminating or coating the label with protective varnish against external influences during transportation and increase the service life, especially in conditions far from room conditions. Labels are glued to the bottle or to the package, and are divided according to where they are glued and their shape:

- front labels – are placed on the front of the bottle or box;

- counter-labels – back label, located on the back of the bottle;

- shoulder labels – are located in the „shoulder” area of the bottle (can), located on top of the front label;

- labels to be affixed near the neck of the bottle – are attached to the neck of the bottle.

There are labels from:

- synthetic paper;

- design label paper (metallized, textured, pearlescent);

- classic coated label paper;

- polymeric film.

It should be noted that all self-adhesive paper is waterproof and antifungal. Protective coating of paper is not applied if it is not planned to transport and store the labeled package.

To decorate the bottle of alcohol are used papers with texture of different kinds used for labels on wine, cognac, whiskey. Good quality label paper is in itself a sign of the originality and authenticity of alcohol. In addition, we can also offer foil stamping and embossing.

Glue (adhesive) for labels in the beverage industry

Depending on what kind of label the adhesive is designed for, there are more than ten types, with a wide variety of adhesion conditions. The adhesive retains its qualities when cooled or condensed, i.e. it has a wide temperature range. There is a special moisture-resistant glue that is designed for labeled bottles that are cooled in a container with ice.

The adhesive is divided into permanent and removable. A label with a removable adhesive can be re-glued (if necessary) within one day, then the adhesive becomes „permanent”. There is also an adhesive for the labeled bottle, which is designed for recycling. The label with this adhesive can be easily washed off with water.

Sometimes a glass bottle is coated with a special varnish to give it a shiny appearance. This makes it very difficult for the adhesive to adhere to the bottle. It should be added that there is no adhesive that labels wet bottles.

In order to avoid the reaction of the label to humidity and temperature fluctuations, there must be good contact between the adhesive and the bottle to be labeled.

Beverage label printing ink

We use UV inks in the manufacture of beverage labels. UV ink (paint) is more expensive, but since its consumption is half as much because there is no solvent evaporation as in alcohol paint, it becomes more profitable in terms of pricing. In addition, UV ink has many other advantages, such as:

- is printed very accurately on the label

- is resistant to chemical and mechanical influences

- the paint hardens quickly has high adhesion when printing self-adhesive labels to the film material

The specialists of the print shop alleetiketten.de are ready to provide complete information about the characteristics of our labels and provide technological support at all stages of material selection and label production.https://europelabels.com/